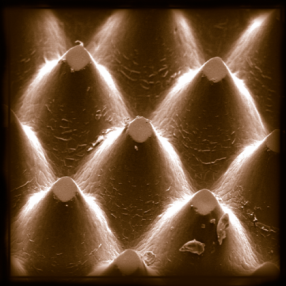

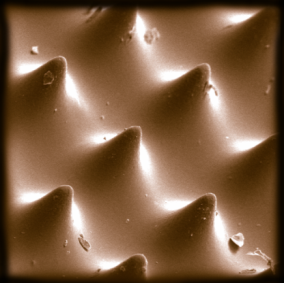

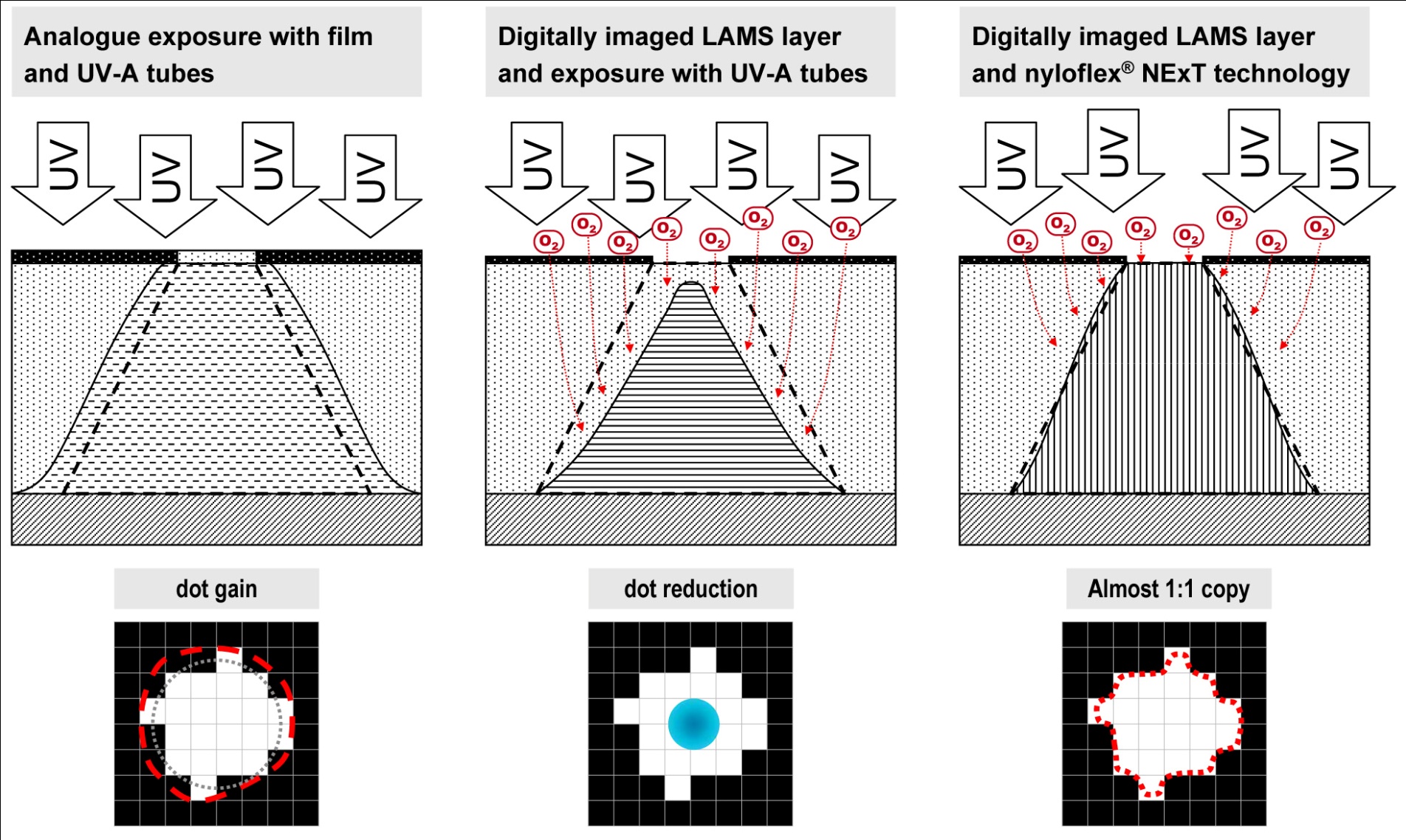

| Flat Top Dots Profile of plate dots

|

|

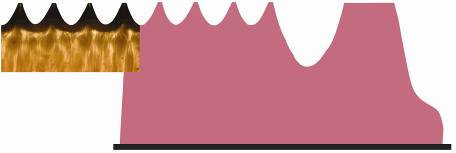

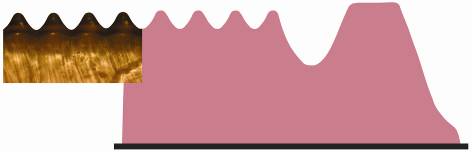

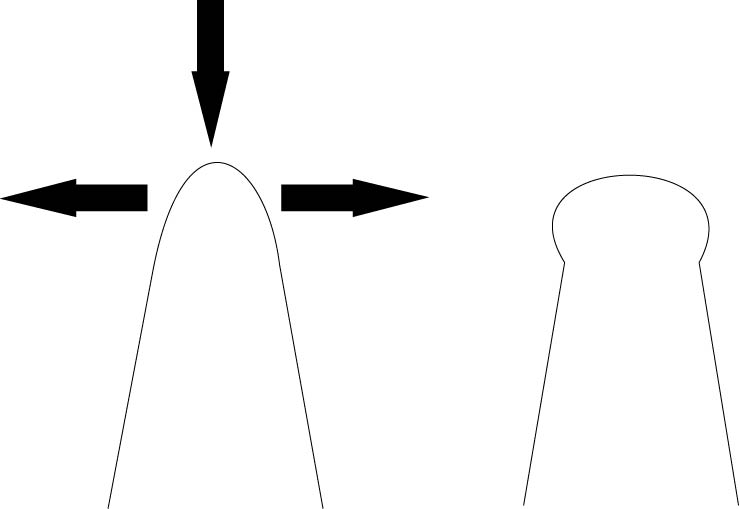

Profile of analog plate dots |

|

|

Profile of digital plate dots |

The dots on analog plate have wide shoulder and flat top. The height of highlight dots are same to solid area. The dots on digital plate have sharper shoulder but round top. The highlight dots are slightly below the solid area.

Oxygen anticipation is the reason for different top and height. With film to keep oxygen from UV exposure, dots on analog plate maintain the sharp edge. For digital plate dots, oxygen makes the top round and go under surface after processing.

|

Analog plate |

Conventional Digital plate |

Flat Top |

The round and under surface dots are not good for printing. More printing pressure has to be applied. More over the round top is easier to deform and consequence in unpredictable dot gain.

Flat top technology is to generate flat dot top like analog plates on digital plates.

Advantages of flat top dots:

1.To make dots smaller. In theory we can go down to 0.4% dots. But we don’t recommend it due to concerns on stability. We would suggest 0.8-1.0%. Hence the tonal range is wider.

2.More smooth gradation.

3.Since the flat top dot is more stable, the set up time is reduced.

4.Less printing pressure is applied. So the plate is not so easy to get dirty.

5.Longer plate life time.

6.Less chance to have gear mark.

7.Higher ink density ( both screening and solid )

How we make flat top dot

DuPont:Digiflow – The purge of Nitrogen keeps Oxygen away. ( installed in our Shanghai and Tianjin branches )

Max. plate format:1067X1524mm

Max. ruling:200lpi

MacDermid: LUX – the lamination keeps Oxygen away ( installed in our Wuhan branch )

Max. plate format:1270X2032mm

Max. ruling:133lpi

|